What is the production process followed by professional kurti manufacturers?

The demand for stylish and comfortable kurtis has been rising steadily across India and globally. Consumers are increasingly looking for quality and unique designs, which makes understanding the production process of professional kurti manufacturers essential. Whether you are searching for kurti manufacturers in India or trying to locate kurti manufacturers near me, knowing how these manufacturers operate will give you insight into the quality, craftsmanship, and value you can expect from your purchase.

Professional kurti manufacturers like HarshCreation follow a meticulous production process to ensure every garment meets high standards. The journey begins with careful planning and ends with the final product ready for distribution. Each stage of production involves specialized skills and advanced technology to maintain consistency, durability, and fashion appeal.

1. Design Conceptualization

Every great kurti begins with a strong design concept. Manufacturers employ experienced designers who stay updated on current trends, fabrics, and regional preferences. These designers sketch patterns, select color palettes, and experiment with embroidery styles and prints. For brands like HarshCreation, this stage is crucial because it defines the uniqueness of their kurtis in a highly competitive market.

During design conceptualization, manufacturers often gather feedback from fashion consultants and potential customers. This helps them refine the design to align with consumer preferences. They may also create mood boards, swatches, and prototypes before finalizing the design for mass production.

2. Fabric Selection

Fabric quality directly influences the comfort and appearance of a kurti. Professional kurti manufacturers in India source fabrics like cotton, silk, chiffon, georgette, and linen from trusted suppliers. They evaluate each fabric for texture, weight, durability, and color retention.

Some manufacturers even invest in custom-dyed fabrics or prints to make their kurtis stand out. This attention to fabric ensures that the final product not only looks appealing but also feels comfortable when worn.

3. Pattern Making and Cutting

Once the design and fabric are finalized, manufacturers create precise patterns that serve as templates for cutting the fabric. Expert tailors or automated machines cut the fabric according to these patterns. Precision is key in this step because even minor errors in cutting can affect the fit and overall look of the kurti.

Professional kurti manufacturers often use advanced cutting machines to minimize fabric wastage while maintaining accuracy. Small-scale manufacturers may still rely on hand-cutting techniques for intricate designs, especially when working with delicate fabrics or detailed embroidery.

4. Stitching and Assembly

After cutting, the kurti pieces are sent to the stitching department. Skilled tailors assemble the garments with attention to detail, ensuring perfect seams and alignment. Modern kurti manufacturers near me often use a combination of machine stitching and hand finishing, especially for premium collections.

Stitching is not just about joining pieces; it also involves reinforcing stress points, attaching linings, and adding decorative elements like lace or borders. For example, HarshCreation emphasizes meticulous stitching to enhance the garment’s durability and elegance.

5. Embroidery, Prints, and Embellishments

Many kurtis feature embroidery, prints, or embellishments that define their style. Manufacturers use various techniques such as hand embroidery, machine embroidery, block printing, or screen printing to decorate the fabric.

High-end kurti manufacturers take great care in this stage to ensure uniformity and accuracy in patterns. For embroidered kurtis, threads, beads, and sequins are carefully placed, enhancing the garment’s visual appeal without compromising comfort.

6. Quality Control

Quality control is a critical step that professional kurti manufacturers in India cannot overlook. Each kurti undergoes thorough inspection to check for stitching errors, color consistency, fabric defects, and accurate sizing.

Manufacturers like HarshCreation implement multiple quality checks during production. Any defective or substandard product is either reworked or discarded. This rigorous process ensures that customers receive kurtis that meet high-quality standards consistently.

7. Finishing and Packaging

The finishing process involves ironing, steaming, and sometimes washing the kurti to ensure it is ready to wear. Buttons, zippers, and hooks are securely attached, and threads are trimmed to give the garment a polished look.

Packaging is equally important for presentation and protection. Manufacturers often use branded packaging to enhance the customer experience and prevent damage during shipping. Proper packaging also reflects the brand’s professionalism and commitment to quality.

8. Distribution and Supply Chain

Once the kurtis are ready, manufacturers distribute them to retail stores, online marketplaces, or directly to customers. Efficient supply chain management ensures timely delivery and maintains inventory levels to meet demand.

For businesses and individuals searching for kurti manufacturers near me, understanding the distribution process helps ensure that they receive products promptly and in excellent condition.

Conclusion

The production process followed by professional kurti manufacturers is detailed, structured, and quality-driven. From design conceptualization to fabric selection, stitching, finishing, and distribution, every step is carefully managed to produce kurtis that combine style, comfort, and durability. Brands like HarshCreation exemplify excellence in this industry, adhering to high standards to satisfy both domestic and international customers.

Whether you are looking for kurti manufacturers in India or searching for kurti manufacturers near me, it is clear that the journey from concept to final product involves skilled craftsmanship, advanced technology, and rigorous quality checks. Understanding this process not only helps buyers make informed decisions but also highlights the dedication and effort invested in creating each beautiful kurti.

FURTHER READING...

How do kurti manufacturers set their wholesale prices?

October 4, 2025

Can Beginners Use Tattoo Needle Cartridges?

September 27, 2025

What Makes Braided Wigs a Popular Choice for Stylish Looks?

September 27, 2025

How can I partner with kurti manufacturers for retail or online sales?

September 26, 2025

What qualifications should I look for in a general contractor?

September 22, 2025

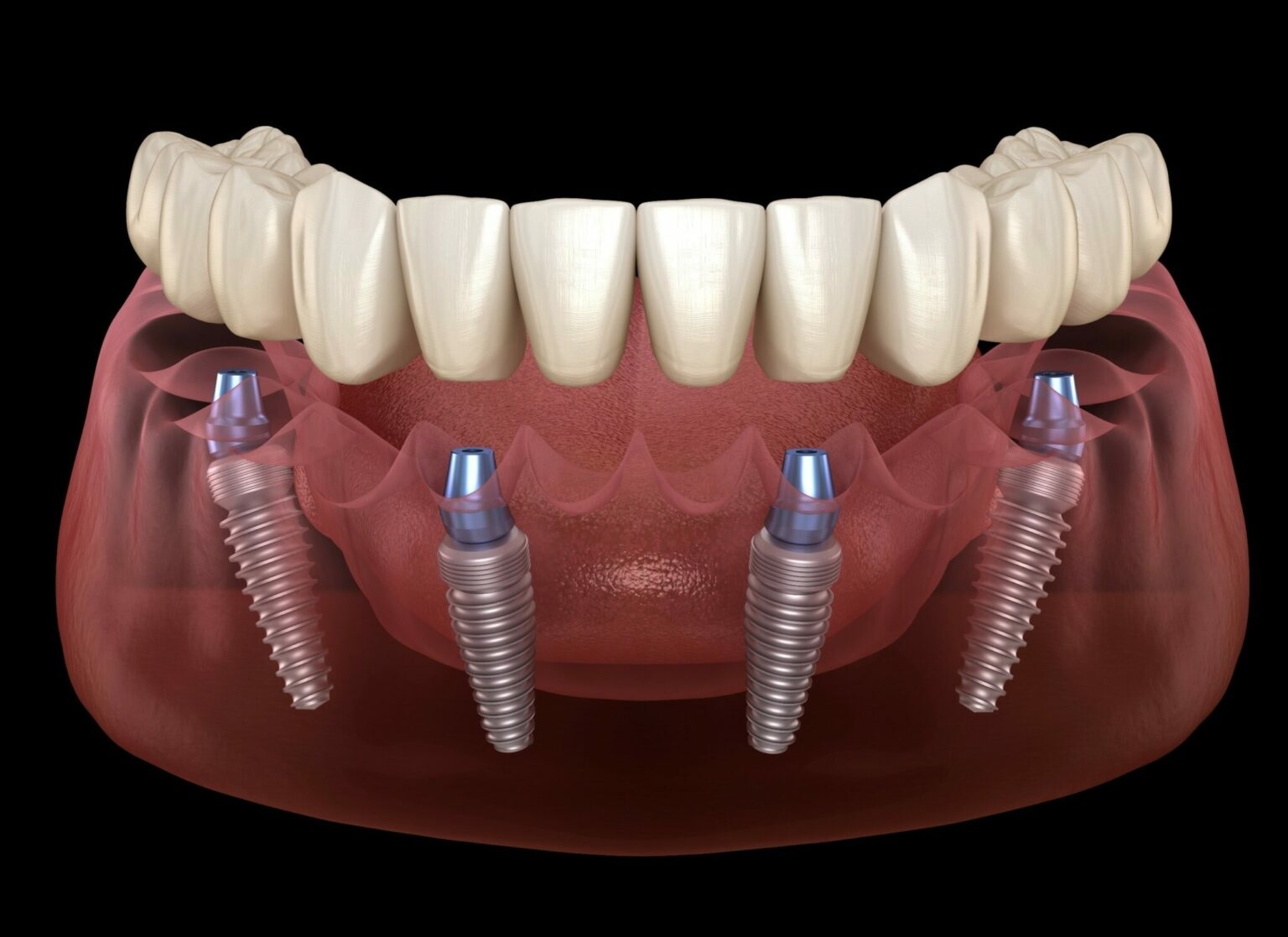

What Are Dental Implants for One Missing Tooth?

September 19, 2025

Latest - post

Category

- ! Без рубрики (1)

- 1k (6)

- 1win-oyna (1)

- 1win-uz-kirish.org (1)

- 1x (1)

- 1xbet (1)

- 1xbet Casino AZ (8)

- 1xbet Korea (1)

- 1xbet russian (9)

- 1xbet russian1 (2)

- 1xbet-india-online.in3 (1)

- 1xbet-kirish.com (1)

- 1xbetsenegal.win (1)

- 22bet Österreich (1)

- a16z generative ai (2)

- abukingcasinoportugal.com (1)

- acrataofficial.com (1)

- adonnasbakery.net (1)

- Ai News 2025 (1)

- akss.uz (1)

- americanfoodshop.it (1)

- amonbet.us (1)

- amonbetuk.uk (1)

- answer (1)

- answers (2)

- appleoffortune.net (1)

- ateliermasomi.com (1)

- aviamasters-games.net (1)

- aviatorbet.co.uk (1)

- ballonixgame.win (1)

- basswin.us (1)

- bchsfoundation.org (1)

- bdmbetitalia.com (1)

- bdmbetportugal.com (1)

- betonred-australia.net (1)

- betonred-cz.org (1)

- betonreddeutschland.com (1)

- betonredespana.net (1)

- betonredfrance.com (1)

- betonreditaly.net (1)

- betonredpl.win (1)

- betonredportugal.net (1)

- betsafecasino.uk (1)

- betsafeperu.org (1)

- betting (1)

- bigbassbonanza.cc (1)

- bigbasssplash.cc (1)

- bigbasssplash.com.es (1)

- bigbeverage.net (1)

- billionairespincz.com (1)

- billionairespinespana.com (1)

- bizzo.at (1)

- blog (134)

- bookhippo.uk (1)

- Bookkeeping (3)

- bragdonhousebb.com (1)

- Business (15)

- Buy Semaglutide (1)

- candy-spinz-casino.com.de (1)

- candyspinz.us (1)

- candyspinzespana.com (1)

- cascbar.co.uk (1)

- cashorcrash.org.uk (1)

- cashwinosterreich.com (1)

- casino (14)

- casino en ligne argent reel (1)

- casino en ligne fr (10)

- casino utan svensk licens (1)

- casino zonder crucks netherlands (11)

- casino-days.us (1)

- casinoinfinityespana.com (1)

- casinonicaustralia.net (1)

- chicken-road-game.org.uk (1)

- chicken-road-it.org (1)

- chicken-road-online.net (1)

- chicken-road2.co.uk (1)

- chicken-road2.in (1)

- chicken-road2.us (1)

- chickencross-es.com (1)

- chickencrossavis.com (1)

- chickencrossgame.co.uk (1)

- chickengamegambling.us (1)

- chickenroadavis.net (1)

- chickenroadespana.com (1)

- chickenroadgame.cc (1)

- ciispecialabilityjobs.in (1)

- clovermagic.us (1)

- clovermagiccasino.us (1)

- cresus-casino.us (1)

- crownplaygreece.com (1)

- czdrops25monobrands (1)

- destination-fremtiden.dk (1)

- drivein.hr (1)

- dropthebossgame.org.uk (1)

- emmeessentials.co (1)

- Environment (10)

- eyeofhorus.cc (1)

- fortuneoxplataforma.com (1)

- funkyaardvark.co.uk (1)

- garden2table (1)

- gates-of-valhalla.com (1)

- gatesofolympusslot.cc (1)

- gatesuperscatter.org (1)

- godsgypsy.com (1)

- gopbeavercounty.org (1)

- grandearmadio.com (1)

- heyspincasino.uk (1)

- Home (820)

- hotslotspl.net (1)

- hrcarers.org.uk (1)

- hudsunmedia.com (1)

- huffnmorepuff.us (1)

- imvest.it (2)

- irwincasino-pl.com (1)

- itreadynetwork.org (1)

- ivibetcasino.us (1)

- ivibetkasyno.net (1)

- jamesbrausch.com (1)

- jonbet.br.com (1)

- kampo-view.com (1)

- kycoroners.com (1)

- lalabetnederland.net (1)

- legacyofdeaddemo.com.de (1)

- lepharaohslot.us (2)

- locandadelcolonnello.it (1)

- lucky-mister.net (1)

- lucky7-casino.us (1)

- Marketing (11)

- marniegrundman.com (1)

- Medical (11)

- megajokernetent.com (1)

- megajokerslot.net (1)

- Monobrand (16)

- monsterslots.uk (1)

- mostbet (1)

- mostbet ozbekistonda (1)

- mostbet-azerbaycan-giris (1)

- mostbet-oyna (1)

- NEW (1)

- News (3)

- nextstageco.com (1)

- ocbombers.com (1)

- oddboy.nz (1)

- olympecasino.us (1)

- olympecasinofrance.net (1)

- oscarspin.us (1)

- oscarspinespana.com (1)

- oscarspinportugal.com (1)

- PariMatch India (1)

- penaltyshootout.us (1)

- pikarimai.co.nz (1)

- Pirots SE (1)

- playojo.games (1)

- playregalfrance.net (1)

- playuzu.games (1)

- plinko (12)

- plinko-official.com (2)

- plinkogamecasino.net (1)

- plinkogamedownload.in (1)

- plinkorecensioni.org (1)

- Post (20)

- prava-osi.hr (1)

- ragingrhino.org (1)

- ready_text (2)

- Relationship (10)

- reviewer (42)

- ricordiamocidellinfanzia.it (1)

- ripper-casino.us (1)

- rippercasinoespana.com (1)

- rjlprecisioneng.co.uk (1)

- roll-x-game.net (1)

- rollx-game.org (1)

- Roobet Official Website in India (1)

- roobetnz.com (1)

- rubyfortune.world (1)

- slots-magic.com.de (1)

- Sober living (2)

- space-interiors.it (1)

- spacexy.co.uk (1)

- spain (1)

- spin-casino-chile.net (1)

- spinangacasinogreece.net (1)

- spincasino-es.com (1)

- spincasinoromania.com (1)

- spingranny.us (1)

- spingrannyportugal.com (1)

- spinmama-de.com.de (1)

- spinmama-pt.com (1)

- spinmamaespana.com (1)

- spinmamafrance.net (1)

- spinmamaitaly.net (1)

- stockx.co.nz (1)

- sunofegypt3.us (1)

- superacedemo.net (1)

- sweet-bonanza-germany.com (1)

- sweetbonanzaslot.us (1)

- tedxmarseille.com (1)

- test (1)

- tfsvl.co.uk (1)

- timclarkband.com (1)

- tuopreventivatore.it (2)

- twiceastranger.net (1)

- twincasino-sv.com (1)

- twincasino.us (1)

- uk (1)

- uncategorized (1)

- uniquecasinoespana.net (1)

- vegasino-ie.com (1)

- Vegastars Casino Australia (1)

- very-well-casino.org.uk (1)

- wbcommunitytrust.co.uk (1)

- wbcommunitytrust.co.uk2 (1)

- Wettigo Suisse – agenceapocope.com (1)

- wildrobincasino-de.com (1)

- wildrobinfrance.com (1)

- win-unique-casino.org (1)

- winvegasplus.org (1)

- yayas.uk (1)

- сателлиты (2)

- сеточный домен (3)

- 카지노사이트 – onlifezone.com (1)

- 카지노사이트추천 (1)