How do kurti manufacturers balance quality with affordability?

Kurti manufacturers operate in a highly competitive fashion market where customers expect stylish designs, durable fabrics, and reasonable pricing — all at the same time. Balancing quality with affordability is not accidental; it is the result of deliberate planning, smart sourcing, efficient production, and deep market understanding. Today’s successful kurti producers, especially wholesale kurti manufacturers in jaipur, have refined their processes to deliver garments that look premium without pushing costs beyond reach.

Let’s explore how manufacturers achieve this delicate balance while continuing to satisfy both retailers and end customers.

Smart Fabric Sourcing Without Compromising Standards

Quality begins with fabric selection. Kurti manufacturers know that material defines comfort, durability, and appearance. Instead of opting for the cheapest fabrics available, they build long-term relationships with textile suppliers to secure high-quality materials at negotiated bulk rates.

By purchasing in large quantities, manufacturers reduce per-unit costs while maintaining consistency in fabric texture and color. Jaipur, known for its textile heritage, offers easy access to cotton, rayon, blends, and specialty fabrics. This proximity lowers transportation costs and enables quicker quality checks. As a result, wholesale kurti manufacturers in jaipur maintain fabric excellence without inflating production expenses.

Efficient Production Planning

Manufacturers rely on streamlined production systems to minimize waste and maximize output. Modern cutting techniques, digital pattern making, and batch production reduce fabric wastage and labor inefficiencies. Every saved inch of material contributes to affordability.

Factories also schedule production runs strategically. Instead of producing small batches that increase overhead costs, they create scalable production cycles. This efficiency spreads operational expenses across larger quantities, keeping prices competitive while preserving garment quality.

An anarkali kurti factory jaipur, for example, often specializes in repeatable silhouettes. By perfecting specific designs, manufacturers optimize stitching processes and finishing techniques. Skilled workers perform tasks faster and more accurately, ensuring quality remains consistent even at scale.

Skilled Craftsmanship Meets Technology

While automation supports efficiency, craftsmanship remains central to kurti manufacturing. Skilled artisans handle embroidery, stitching, finishing, and detailing with precision. Their expertise ensures garments maintain a refined appearance, strong seams, and long-lasting wear.

Manufacturers balance labor costs by integrating technology where appropriate. Automated cutting machines and quality inspection tools reduce manual errors, but artisans still oversee final finishing. This hybrid model keeps labor expenses manageable while preserving the handcrafted quality that customers value.

Design Optimization for Cost Control

Creative design does not always require expensive embellishments. Smart manufacturers develop patterns that maximize aesthetic appeal using cost-effective techniques. Thoughtful color combinations, printed motifs, and minimal embroidery create stylish garments without excessive material or labor costs.

Design teams also consider fabric efficiency during pattern development. Patterns that minimize leftover fabric directly reduce production expenses. This design-conscious approach allows manufacturers to produce fashionable kurtis that remain affordable.

Quality Control at Every Stage

Maintaining affordability does not mean ignoring quality checks. Reputable kurti manufacturers implement multi-stage inspections to catch defects early. Early detection prevents costly rework and reduces product returns, both of which protect profit margins.

Quality teams inspect stitching strength, color consistency, measurements, and finishing details. When manufacturers maintain strict standards, they build trust with retailers and customers. This trust encourages repeat business, allowing manufacturers to operate at higher volumes and sustain competitive pricing.

Bulk Manufacturing and Economies of Scale

Scale plays a major role in balancing quality and affordability. Larger production volumes reduce the cost per unit by spreading fixed expenses — such as equipment, utilities, and labor — across more garments.

Jaipur’s manufacturing ecosystem supports large-scale operations. Shared supplier networks, skilled labor pools, and established logistics systems enable wholesale kurti manufacturers in jaipur to produce efficiently. These economies of scale allow them to deliver high-quality kurtis at prices suitable for wholesale markets.

Supplier Relationships and Inventory Management

Strong vendor partnerships extend beyond fabric sourcing. Manufacturers collaborate closely with dyeing units, printing houses, packaging providers, and accessory suppliers. These partnerships ensure consistent quality while securing favorable pricing structures.

Effective inventory management also reduces hidden costs. Manufacturers forecast demand accurately, preventing overproduction and excessive storage expenses. Efficient stock control allows them to allocate resources wisely and maintain affordability without sacrificing garment standards.

Continuous Process Improvement

Successful kurti manufacturers constantly refine their workflows. They monitor production metrics, analyze customer feedback, and adopt new techniques that improve efficiency. Even small improvements — such as reducing stitching time or improving fabric cutting layouts — compound into significant savings.

Factories that specialize in Anarkali designs often refine pleating, lining, and finishing methods to maintain elegance while reducing production time. An experienced anarkali kurti factory jaipur uses process optimization to preserve signature craftsmanship without inflating costs.

Market Awareness and Customer-Centric Strategy

Manufacturers stay aligned with market trends to avoid producing designs that fail to sell. Trend-driven collections reduce unsold inventory and financial waste. When garments move quickly through retail channels, manufacturers maintain healthy cash flow, which supports competitive pricing.

Customer feedback also shapes production decisions. By understanding what buyers value most — comfort, durability, or style — manufacturers allocate resources effectively. This targeted approach ensures money goes toward features customers truly appreciate.

The Balance That Drives Long-Term Success

Balancing quality with affordability is a continuous effort rather than a one-time strategy. Kurti manufacturers succeed when they combine smart sourcing, skilled craftsmanship, efficient production, and thoughtful design. Jaipur’s manufacturing landscape provides the infrastructure and expertise needed to maintain this equilibrium.

FURTHER READING...

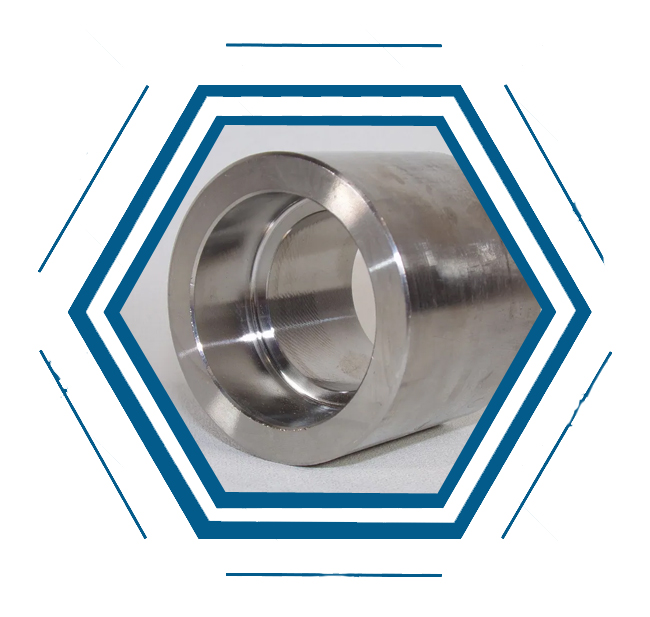

Things Buyers Expect From Stainless Steel Pipe Fittings Manufact

February 4, 2026

Common Mistakes to Avoid When Sourcing Stainless Steel Products

February 4, 2026

Key Uses of Stainless Steel Threaded Rod

February 4, 2026

Key Differences Between Alloy Steel Pipes and Carbon Steel Pipes

February 4, 2026

How Do You Choose the Right Braided Wig for Your Face Shape?

February 4, 2026

Latest - post

Category

- ! Без рубрики (5)

- 10Mostbet (1)

- 11Mostbet (1)

- 12Mostbet (1)

- 1betcasinoitalia.com (1)

- 1Mostbet (1)

- 1xbet020218 (1)

- 1xbet06021 (1)

- 1xbet1 (1)

- 1xbet10 (2)

- 1xbet11 (2)

- 1xbet12 (2)

- 1xbet13 (1)

- 1xbet14 (1)

- 1xbet15 (1)

- 1xbet16 (1)

- 1xbet19 (1)

- 1xbet2 (2)

- 1xbet3 (1)

- 1xbet4 (1)

- 1xbet5 (2)

- 1xbet6 (1)

- 1xbet7 (2)

- 1xbet8 (1)

- 1xbet9 (2)

- 1xcasinoespana.com (1)

- 20betcasinoitalia.com (1)

- 21-casino.us (2)

- 22-bet-bangladesh.com (1)

- 22-bet-italia.com (1)

- 22-bet-pakistan.com (1)

- 22-bet-portugal.com (1)

- 22-bet-sk.com (1)

- 22-bet-suomi.com (1)

- 22betdeutschland.com (1)

- 22betromania.com (1)

- 2Mostbet (1)

- 32red-casino-uk.uk (1)

- 3Mostbet (1)

- 4Mostbet (1)

- 500casinodk.com (1)

- 500casinono.com (1)

- 5Mostbet (1)

- 7bet-no.com (1)

- 7betcasinoit.com (1)

- 7Mostbet (1)

- 8888casinobrasil.com (1)

- 888casinocanada.net (1)

- 888starzbangladesh.com (1)

- 888starzportugal.net (1)

- 8Mostbet (1)

- 9Mostbet (1)

- a16z generative ai (7)

- a16z generative ai 1 (2)

- admiralbetcasinoitalia.com (1)

- admiralcasinodeutschland.com (1)

- adobe generative ai 3 (2)

- ai dating (4)

- Ai News 2025 (1)

- allinbetcasinoitalia.com (1)

- Android (1)

- answer (19)

- answers (23)

- APK (3)

- Arts & Entertainment, Celebrities (1)

- ballycasinocanada.com (1)

- bc-game-france.com (1)

- bc-game-uk.uk (1)

- bcgame-turkiye.com (1)

- bcgame03025 (1)

- bcgame2 (1)

- bcgame26011 (1)

- bcgame27012 (1)

- bcgame27013 (1)

- bcgame31011 (1)

- bcgameaustralia.com (1)

- bcgamee-ro.com (1)

- bcgameportugal.com (1)

- bestcasino (1)

- bestcasinos1 (1)

- bet-passioncasinoitalia.com (1)

- betandreas2 (1)

- betandreas3 (1)

- betandres4 (1)

- betcasino02021 (1)

- betcasino020214 (1)

- betcasino04021 (1)

- betcasino05022 (1)

- betcasino05023 (1)

- betcasino06021 (1)

- betcasino1 (5)

- betcasino1701 (1)

- betcasino2 (3)

- betcasino27013 (1)

- betcasino28014 (1)

- betcasino28015 (1)

- betcasino29016 (1)

- betcasino29017 (1)

- betcasino3 (3)

- betcasino30018 (1)

- betcasino30019 (1)

- betcasino4 (2)

- betcasino5 (1)

- betcasino6 (1)

- betcasinos1 (1)

- betfredcasino.us (1)

- bethardcasinoespana.com (1)

- betifycasinoitalia.net (1)

- betpandanederland.com (1)

- betssondk.com (1)

- betssonlt.com (1)

- betting29011 (1)

- bettingcasino1 (1)

- bettingcasino2 (1)

- bettingcasino3 (1)

- bettingcasino4 (1)

- bettingcasino5 (1)

- bettycasinocanada.org (1)

- betwiner1 (1)

- betwinner07022 (1)

- betwinner1 (1)

- betwinner2 (3)

- betwinnernigeria.org (1)

- betwoon-2026casino.top (1)

- bigbooscasinocanada.com (1)

- bigboostcasinoindia.com (1)

- bitcoins casino (1)

- blog (1,867)

- bobcasinofr.com (1)

- Bookkeeping (5)

- bookmakers1 (1)

- boomerang-casino-de.net (1)

- boomerangcasino-espana.com (1)

- bovadacanada.org (1)

- bovadaindia.com (1)

- boylecasinoie.com (1)

- boylesports-ireland.com (1)

- br-333casino.com (1)

- Business (32)

- bwin-casino.us (1)

- bwincasinobr.net (1)

- captaincookscasinocanada.net (1)

- casa-pariurilor.uk (1)

- casapariurilor-hungary.com (1)

- casapariurilor-it.com (1)

- casapariurilor-nl.com (1)

- casapariurilor.us (1)

- casimbacasino.uk (1)

- casimbacasino.us (1)

- Casino (45)

- casino-lab-fr.com (1)

- casino01261 (1)

- casino01262 (1)

- casino01263 (1)

- casino01264 (1)

- casino01265 (1)

- casino01266 (1)

- casino03021 (1)

- casino03022 (1)

- casino04022 (1)

- casino05025 (1)

- casino05026 (1)

- casino06025 (1)

- casino140126 (1)

- casino1601 (1)

- casino17011 (1)

- casino17012 (1)

- casino18012 (1)

- casino21014 (1)

- casino21015 (1)

- casino22016 (1)

- casinobest01022 (1)

- casinobest1 (1)

- casinobest2 (1)

- casinobest30012 (1)

- casinobest31011 (1)

- casinobet1 (1)

- casinobet2 (1)

- casinobet3 (1)

- casinobet31 (1)

- casinobet310110 (1)

- casinobet33 (1)

- casinocz1 (1)

- casinogame1 (1)

- casinogame2 (1)

- casinogame3 (1)

- casinogame4 (1)

- casinojaya9 (1)

- casinoonline0402 (1)

- casinoonline05022 (1)

- casinoonline06021 (1)

- casinoonlineslot1 (1)

- casinoonlineslot2 (1)

- casinoonlineslot3 (1)

- casinos-nongamstop1 (1)

- casinos-nongamstop2 (1)

- casinos-nongamstop3 (1)

- casinos-nongamstop4 (1)

- casinoslot4 (1)

- casinoslot5 (1)

- Casinoszonder3 (1)

- casinoudenrofus (2)

- casumocasino-nz.com (1)

- cityoflondonmile (1)

- ck999 (4)

- cocoacasinosouthafrica.com (1)

- Computers, Games (21)

- coral-casinouk.uk (1)

- cosmocasinonz.com (1)

- dashbetethiopia.com (1)

- dating (10)

- davinci-goldcasino.us (1)

- daznbetdeutschland.com (1)

- daznbetitalia.com (1)

- diplomm-i1 (1)

- diplomm-i2 (1)

- diplomrums1 (2)

- diplomrums3 (1)

- domusbetcasinoitalia.net (1)

- dragonmoney3 (1)

- dripcasinobrasil.com (1)

- dripcasinolatvia.com (1)

- egu-diplom1 (1)

- egu-diplom2 (1)

- egu-diplom3 (1)

- EN (2)

- energycasinofi.com (1)

- enrachacasinoespana.com (1)

- Environment (8)

- fastbetcasinoitalia.com (1)

- fezbetcasinoespana.com (1)

- Finance, Credit (1)

- Finance, Currency Trading (1)

- Finance, Investing (1)

- Finance, Loans (1)

- fivebetcasinoitalia.com (1)

- Forex Trading (2)

- fortuna-casinopl.com (1)

- fortunacasino.uk (1)

- fortunacasinocz.com (1)

- forum (1)

- FreeSpinscasino1 (1)

- freshcasinobrasil.com (1)

- freshcasinode.com (1)

- fun-casino.us (1)

- fun-casinouk.uk (1)

- galabingoo.us (1)

- gamdom-ro.com (1)

- gamdom-uk.uk (1)

- gamdomaustria.com (1)

- gamdomcanada.com (1)

- gamdomdanmark.com (1)

- gamdomportugal.com (1)

- game (2)

- game, ck999 (3)

- Games (6)

- gaming (2)

- GamStopCasinos1 (1)

- gemes, casino (8)

- getsbetcasinoespana.com (1)

- ggbet-chl.com (1)

- ggbet-us.us (1)

- ggbetdeutschland.com (1)

- ggbethu.net (1)

- ggbetperu.com (1)

- giochi (3)

- gioco (2)

- gokspel (1)

- goldbet-it.net (1)

- goldbetcasinofrance.com (1)

- goldenbet-angola.com (1)

- goldenbetsv.com (1)

- google bard ai launch date 1 (1)

- gosz-diplomas3 (1)

- gosz-diplomas4 (1)

- gosz-diplomas6 (1)

- gratoganacasinoespana.com (1)

- gutscasinonz.net (1)

- hash-bcgame.com (1)

- hellspin-casino-canada.com (1)

- Home (192)

- Home & Family, Home Improvement (1)

- hypercasino-fr.com (1)

- inbetaustria.com (1)

- inbetbelgium.com (1)

- inbetespana.com (1)

- inbetuk.uk (1)

- inbetus.us (1)

- info (5)

- intensecasinoitalia.com (1)

- Internet Business, Audio-Video Streaming (1)

- Internet Business, Ecommerce (1)

- Internet Business, Email Marketing (2)

- Internet Business, Security (1)

- Internet Business, Web Design (1)

- IPTV (1)

- isitfair (1)

- jackbit-us.us (1)

- jackpot-village-uk.uk (1)

- jaya91 (2)

- jaya92 (1)

- Jeux (5)

- jokerbet-uk.uk (1)

- jokerbetturkiye.com (1)

- jos-trust1 (1)

- jos-trust2 (1)

- joya93 (1)

- karambacasino.us (1)

- kingmakercasinoespana.net (1)

- ladbrokescasinous.us (1)

- legianocasinoespana.com (1)

- lottoland-uk.uk (1)

- lottolandcasino.us (1)

- luckiacasinoespana.com (1)

- luckycasinoespana.com (1)

- luckydreamsaustria.com (1)

- luckyvip-id.com (1)

- luxurycasinonz.net (1)

- magicredcasinode.com (1)

- marketasdiplomas1 (1)

- marketasdiplomas2 (1)

- marketasdiplomas3 (1)

- Marketing (11)

- maxbetcasinoitalia.com (1)

- Medical (11)

- mega-casinobangladesh.com (2)

- megacasinoespana.com (1)

- megaparicasinoitalia.com (1)

- meilleur-casino.uk (1)

- meilleurcasinoenlignefrance.net (1)

- melbet-egypt-online.net (1)

- melbet-uzonline.com (1)

- melbetbrasil.net (1)

- melbetcamerounonline.com (1)

- melbetespana.net (1)

- melbetkz.net (1)

- million-casino-fr.com (1)

- million-casino-nl.com (1)

- millioncasinoromania.com (1)

- Mostbet (2)

- mostbet скачать (1)

- mostbet скачать ru (1)

- mostbet1 (1)

- mostbet3 (1)

- mostbetcasino-bangladesh.com (1)

- mostbetcasinode.com (1)

- mostbetcasinoportugal.com (1)

- mrgreencasino.uk (1)

- mrgreencasinodk.com (1)

- mrpunter-uk.uk (1)

- mrq-casino.us (1)

- mummysgoldcasinonz.net (1)

- mystakecasino.us (1)

- mystakecasinofrance.net (1)

- netbetcasinofinland.com (1)

- News (37)

- news2026 (3)

- newvegascasino.us (1)

- newvegascasinoes.com (1)

- newvegascasinoespana.com (1)

- NL (1)

- NonGamStopCasinos (1)

- novibet-brasil.com (1)

- novibet-chile-cl.com (1)

- novibet-uk.uk (1)

- novibetcasinoespana.com (1)

- novibetcasinoitalia.com (1)

- novibetturkiye.com (1)

- nyspins-casino-uk.uk (1)

- olybetcasinoitalia.com (1)

- onecasinonz.org (1)

- oneplaycasinoespana.com (1)

- onlinecasino1 (1)

- onlinecasino1401 (1)

- onlinecasino2 (1)

- onlinecasinoslot1 (1)

- onlinecasinoslot13 (1)

- onlinecasinoslot14 (1)

- onlinecasinoslot15 (1)

- onlinecasinoslot16 (1)

- onlinecasinoslot18 (1)

- onlinecasinoslot19 (1)

- onlinecasinoslot2 (1)

- onlinecasinoslot20 (1)

- onlinecasinoslot23 (1)

- onlinecasinoslot24 (1)

- onlinecasinoslot26 (1)

- onlinecasinoslot27 (1)

- onlinecasinoslot28 (1)

- onlinecasinoslot29 (1)

- onlinecasinoslot3 (1)

- onlinecasinoslot30 (1)

- onlinecasinoslot31 (1)

- onlinecasinoslot32 (1)

- onlinecasinoslot34 (1)

- onlinecasinoslot35 (1)

- onlinecasinoslot36 (1)

- onlinecasinoslot37 (1)

- onlinecasinoslot39 (1)

- onlinecasinoslot4 (1)

- onlinecasinoslot40 (1)

- onlinecasinoslot41 (1)

- onlinecasinoslot5 (1)

- onlinecasinoslot6 (1)

- onlinecasinoslot7 (1)

- onlinecasinoslot8 (1)

- onlinemarriageregistration.com x (1)

- palmsbetdeutchland.com (1)

- palmsbetnl.com (1)

- palmsbetperu.com (1)

- palmsbetswitzerland.com (1)

- paradise8-casino.uk (1)

- paradise8-casino.us (1)

- parimatch-us.us (1)

- parimatchbrasil.net (1)

- parimatchcanada.net (1)

- pauseandplaycasinoespana.com (1)

- pin-up-casinouzbekistan.com (1)

- pin-up-kzcasino.com (1)

- pinco-casino-downloads.top (1)

- pinco-casino-official2026.top (1)

- pinco-cazino-kazakhstan.top (1)

- pinco-cazino-login.top (second pack) (1)

- pinup-aviator2026.top (1)

- pinup-cazino-kz.top (1)

- pinup-kazakhstan-kk.top (1)

- pinup-kazino-kz.top (1)

- pinup-kazino-login.top (1)

- pinup-kz-officiall.top (1)

- pinup-official-kz.top 3 (1)

- pinup-zerkalo2026.top (1)

- platincasinoespana.com (1)

- playzee.uk (1)

- plexbetcasinoitalia.com (1)

- plinko_pl (2)

- plinkogamecasino.cc (1)

- Post (11)

- princess-casino.uk (1)

- princesscasino.us (1)

- princesscasinofr.com (1)

- quickwincasinoespana.com (1)

- real money pokies apps (2)

- Relationship (10)

- rizkcasino-canada.com (1)

- rizkcasino.uk (1)

- rizkcasinoat.com (1)

- rizkcasinosuomi.com (1)

- rocketplaycasinocanada.net (1)

- rollbitcanada.com (1)

- rollbitcasino.uk (1)

- rollbitdeutschland.com (1)

- rollbitlithuania.com (1)

- roobetcasinoespana.com (1)

- rooli-casinonz.net (1)

- rubyfortunecasinonz.net (1)

- saharasandscasinoespana.com (1)

- Self Improvement, Coaching (1)

- selust.com 1000 (1)

- shuffle-casino.uk (1)

- siti-scommesse2 (1)

- sky-casino-uk.uk (1)

- skybet-turkey.com (1)

- skybetcasinoitalia.com (1)

- slotcasini1 (1)

- Slots (13)

- slotstarscasinoespana.com (1)

- slovenska-casina1 (1)

- slovenska-casina2 (1)

- slovenska-casina3 (1)

- snaicasinoitalia.com (1)

- Sober Living (2)

- Software (1)

- spain (27)

- spel (1)

- Spellen (5)

- Spiele (2)

- spielen (2)

- spile (1)

- spillen (1)

- spinangacasinoespana.com (1)

- spincasinoespana.com (1)

- spinwinera-cz.com (1)

- spinwineraaustralia.com (1)

- spinwineracanada.com (1)

- spinwineradeutschland.com (1)

- spinwinerapolska.com (1)

- spinwineraportugal.com (1)

- sportingbet-india.com (1)

- sportingbet-us.us (1)

- sportingbetmagyar.com (1)

- Sportwetten1 (1)

- stakecasinoitalia.net (1)

- sunaonal.com 1000 (1)

- superbetcasinosouthafrica.com (1)

- sushi 17 (1)

- sweet-bonanza-france.com (1)

- sweet-bonanza-italy.com (1)

- sweet-bonanza-romania.com (1)

- tegory% (1)

- Television (1)

- Test (1)

- thephonecasino.us (1)

- thisisvegascasinode.com (1)

- tombola-chile.com (1)

- tombola-in.com (1)

- tombola-us.us (1)

- tombolaargentina.com (1)

- tomboladanmark.com (1)

- tombolaes.com (1)

- tombolait.com (1)

- total-casino-de.com (1)

- total-casinouk.uk (1)

- totocasinode.com (1)

- totocasinonl.net (1)

- totocasinopl.com (1)

- traditioncasinoespana.com (1)

- travel (2)

- truefortunecasinode.com (1)

- Uncategorized (1)

- uncategorized (22)

- unibet-uk.uk (1)

- unibetbulgaria.com (1)

- unibeteesti.net (2)

- unibetit.net (1)

- unibetnorge.net (1)

- unibetschweiz.com (1)

- vanguardcasinoespana.com (1)

- vavada-austria.com (1)

- vavada-finland.net (1)

- vavada-italia.com (1)

- vavadalv.net (1)

- vbet-france.net (1)

- vbet-sverige.net (1)

- vbet-tr.net (1)

- vbetdeutschland.com (1)

- vbetromania.org (1)

- videoslotscasinose.com (1)

- villentocasinonz.net (1)

- vlad-casino-de.com (1)

- vnebetcasinoitalia.com (1)

- vodds (1)

- voodoodreamssuomi.com (1)

- vulkan-vegas (2)

- wazambacasinoespana.net (1)

- wheelzcasinonz.net (1)

- wildzcasinocanada.org (1)

- williamcasinoespana.com (1)

- winbeatzcz.com (1)

- winbet-brasil.net (1)

- winbet-casino.us (1)

- winbet-france.com (1)

- winbet-ireland.com (1)

- winner-casino-ro.com (1)

- winuniquecasinoespana.com (1)

- yaasscasinoespana.com (1)

- yocasinocasinoespana.com (1)

- zonagiococasinoitalia.com (1)

- Новости Криптовалют (1)

- Новости Форекс (2)

- Финтех (1)

- Форекс Брокеры (3)